Professional Training

Sailing and Boating

Onboard Operations

Cargo Handling Deck Operations Maintenance and Repair Interior and Service Medical SecurityCulture, Law and Policy

Emergency Procedures Communications Legislation Environment and Sustainability Regulations and Policies Health and Wellbeing Fitness and LifestyleExplore Seably

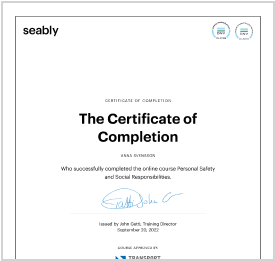

Professional Training

Sailing and Boating

Seably for Business

Subscribe to Seably for Business and give your employees unlimited access to all courses. Build a culture that drives your business forward.